Winter Storm Update

January 31, 2026

As of Monday, Feb. 2, Penske Truck Leasing locations have resumed normal operating hours.

R

[Read more...]Show less

As of Monday, Feb. 2, Penske Truck Leasing locations have resumed normal operating hours.

Each December, National Wreaths Across America Day unites millions of volunteers to honor our nation’s veterans. Penske was proud to participate again this year, supporting remembrance ceremonies and wreath-laying events at military cemeteries, memorials and historic sites across the country.

Associates and their families joined local wreath-laying ceremonies nationwide, including events at Arlington National Cemetery in Arlington, Virginia; Fort Indiantown Gap National Cemetery in Annville, Pennsylvania; Jefferson Barracks National Cemetery in St. Louis, Missouri; Raleigh National Cemetery in Raleigh, North Carolina; and historic sites in Chester, Virginia.

In St. Louis, Penske associate Kimberlee Sexton placed a wreath at her father’s gravesite at Jefferson Barracks National Cemetery — a personal tribute that reflected the day’s deeper meaning.

Additionally, Epes Transport, a Penske Company, played an essential role by providing two trucks and two drivers to deliver wreaths to Arlington, Virginia, and Raleigh, North Carolina, helping ensure thousands of wreaths reached their destination.

Wreaths Across America, a nonprofit organization founded in 1992, began with a single act of gratitude and has grown into a nationwide movement dedicated to remembering fallen heroes, honoring those who serve and teaching future generations the value of freedom.

This year, Penske associates once again demonstrated pride, unity and gratitude, reinforcing our ongoing commitment to service, supporting veterans and making a meaningful difference within the communities we proudly call home.

Penske Transportation Solutions is a 2026 Military-Friendly Gold Employer. The leading transportation services provider’s recruitment and retention of veterans was recognized by VIQTORY, a veteran-owned business and the publisher of the G.I. Jobs and Military Spouses publications.

Kayla Lopez, vice president of memberships, Military-Friendly noted: “earning the Military-Friendly designation is more than a badge; it’s a reflection of deep-rooted values and strategic foresight. These organizations don’t just open doors for veterans, spouses, and service members; they build pathways for lasting impact.”

Penske was given the Military-Friendly Employers designation via an evaluation process that utilized public data sources and proprietary survey responses. The ratings were compiled by combining survey scores with an assessment of the organization’s ability to meet thresholds for recruitment, new hire retention, employee turnover, and promotion and advancement.

“We’re excited to be recognized again as a Military-Friendly Gold Employer,” said Jennifer Sockel, Penske executive vice president of talent and enterprise services. “Our veterans bring exceptional talent and discipline to our organization, helping us move forward together. This designation reinforces our ongoing commitment to creating meaningful opportunities for those who’ve served.”

If you would like to learn more about career opportunities for veterans at Penske, please click here.

By “Move Ahead” Staff

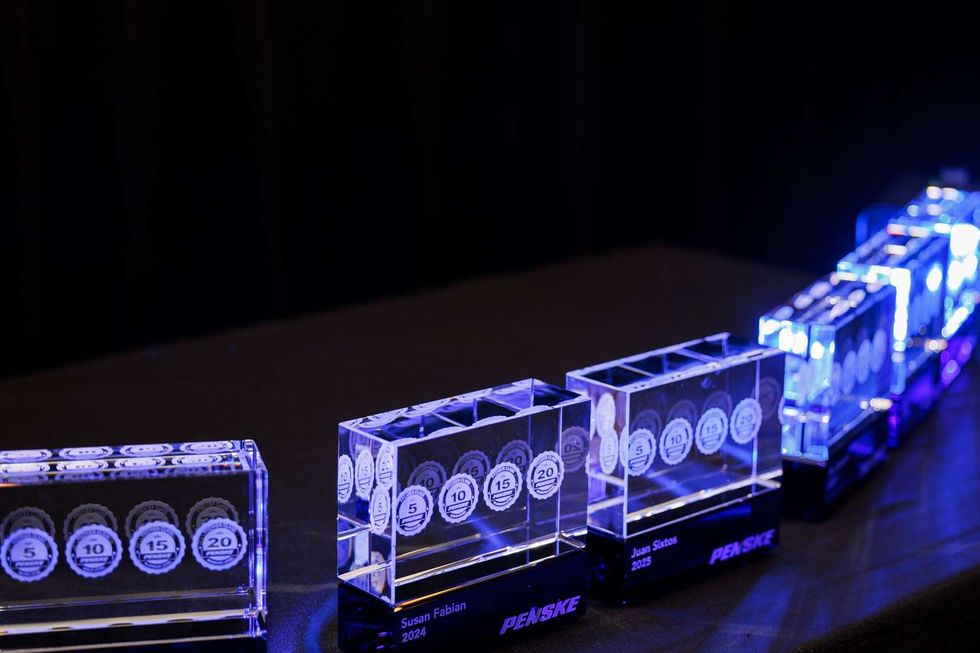

Ten professional truck drivers were recently inducted into Penske Logistics’ 2024 and 2025 Diamond Class.

Inductees have achieved 20 consecutive years of preventable incident- and injury-free driving: a feat attained by less than 1% of Penske drivers, signifying the highest level of safety recognition at the company.

Created to acknowledge and celebrate safety milestones, this accolade is part of Penske Logistics’ Premier Driver Recognition Program. In addition to the Diamond Class, the program recognizes drivers with five, 10 and 15 years of incident- and injury-free driving.

Diamond Class inductees – with their families and supervisors – were invited to a two-day celebration in Pennsylvania to commemorate this accomplishment. They received a sightseeing tour of Philadelphia before departing to Reading, Pennsylvania, for an evening recognition dinner attended by Penske leadership – including Penske Logistics President Jeff Jackson.

“It is with tremendous honor and respect that we induct these Driver Wall of Fame classes,” said Jackson. “Our professional drivers are paramount to our company’s success. They serve as the industry’s gold standard for safety.”

Honorees received awards while posing for photos with Jackson, Safety and Loss Prevention Vice President Aaron Henderson and Senior Vice President of DCC Operations Pete Bayer.

“You are fantastic examples of what safety looks like,” said Bayer. “Our Diamond Class drivers are committed to being the best, every day, and I am incredibly proud to be your teammate.”

Many inductees credit the organization’s commitment to safety for their long-standing success.

“I take it day by day,” said Delio Garcia, professional truck driver. “We live in a fast-paced society, but I make sure to prioritize coming home safely.”

Professional Truck Driver Mike Larmeu echoes this mindset – reaffirming that safety is at the core of Penske Logistics operations.

“It’s important to never get complacent behind the wheel,” said Larmeu.

To further commemorate this achievement, Diamond Class drivers had their name inscribed on the Driver Wall Hall of Fame displayed at company headquarters.

Honorees attended a special ceremony at the wall and took pride in seeing their names added - a reflection of their hard work, commitment to safety and dedication to excellence.

From left to right: Senior Vice President of DCC Operations Pete Bayer, President of Penske Logistics Jeff Jackson, Professional Truck Driver Darrall Headrick and Safety and Loss Prevention Vice President Aaron Henderson.

2024 Diamond Driver Class

2025 Diamond Driver Class

The annual Top Companies list highlights organizations that provide a culture where associates feel valued and respected, and receive quality benefits, continued training and opportunities for development.

Penske is a gold level partner of WIT, supporting WIT’s mission to empower women, celebrate their achievements, and address the challenges they face within the trucking industry. Penske’s support for WIT includes sponsorship of its annual conference and the courtesy transport of WIT’s educational trailer.

Logistics Management magazine, a leading supply chain publication, has recognized Penske Logistics with two gold Quest for Quality Awards.

The company’s transportation management services have been honored. Penske Logistics were category leaders in the areas of order fulfillment and transportation distribution. The other award category was in value-added services, where Penske ranked the highest in order fulfillment.

“There’s little doubt that technology implementation and innovation are key factors enabling 3PLs to remain resilient and grow,” noted magazine contributing editor Karen Theurmer. “Many companies are turning to automation, AI, and IoT to enhance operational efficiency and streamline service offerings—especially for shippers looking to leverage 3PLs to grow their e-commerce.”

Customers can count on Penske Logistics to accelerate their supply chain performance by providing comprehensive transportation and logistics solutions.

By “Move Ahead” Staff

The 2026 Annual Third-Party Logistics Study marks a significant milestone, celebrating its 30th anniversary as a historic chronicler of the U.S. supply chain.

Dr. John Langley, the study’s creator and a Penn State University supply chain professor and emeritus professor at the University of Tennessee, along with sponsors NTT DATA and Penske Logistics, will commemorate this edition by highlighting the most effective ways that the supply chain can collaborate and the emerging technologies that make them run.

The study is available for download at no cost at www.3PLStudy.com.

The publication centers its efforts on three special sections: How the relationships between shippers and 3PLs might evolve from transactional to strategic, successful strategic partnerships, and emerging technologies within the supply chain.

Each year, the research provides a deeper dive into the current state of the 3PL market and tackles contemporary issues like the supply chain’s response to rising tariffs and the crucial role of supply chain talent.

Highlights from the 2026 3PL Study:

According to Dr. Langley: “the 3PL industry has grown and transformed significantly over the past 30 years. Both shippers and providers and managers of supply chain services have responded forcefully to the continually changing and challenging business and supply chain environments.”

“In 30 years of the 3PL study, we’ve tracked countless industry shifts, but this year holds something unique,” said Shanton Wilcox, senior vice president of supply chain consulting at NTT DATA. “For the first time, we see an overlap with a significant and ubiquitous business condition in the global tariffs, coinciding with material advancements in enabling technology, namely AI. This situation provides the motivation and capability for organizations to address the volatility and dynamic nature of this business challenge.”

“We would like to congratulate Dr. Langley for three decades of 3PL Study excellence,” stated Stacy Schlachter, Penske Logistics senior vice president of sales. “This year’s report does a great job of delving deeper into the relationships between shippers and their 3PLs, what translates to the most effective collaborations, and what new technologies matter most to shippers.”

By “Move Ahead” Staff

Private fleets are continuing to exert strength and control over their supply chains, positioning themselves as a value-added transportation solution. Private fleets have increased the number of shipments, freight volume and value of freight hauled for more than 11 years, according to the National Private Truck Council's 2025 Benchmarking Survey.

“Private fleets are capturing enhanced control over the supply chain,” said Tom Moore, executive vice president of the National Private Truck Council. “I think for many years, we've been a cost and customer service-focused community, and now we're talking about adding value back into those corporations that operate private fleets as an extension of their primary business.”

This year’s survey found that private fleets handled 70% of outbound freight moves, down from last year’s 75%. “We gave a little bit back, but we’re still at pre-pandemic levels,” Moore said. “For years and years, that outbound market share percolated between 67% and 68% just like clockwork.”

The number of inbound movements private fleets handle increased to 43% from 35% last year. Historically, private fleets have proven their value proposition on the outbound side of the business. However, the increased visibility, the ability to analyze the data and other strategies that have been beneficial on the outbound side of the business are giving fleets more control over costs and service on inbound moves.

Moore presented the results of the 2025 National Private Truck Council Benchmarking Survey recently. He was joined by Gary Petty, NPTC’s CEO; Jim Lager, executive vice president of sales and rental for Penske Truck Leasing; Mike Schwersenska, general manager of Brakebush Transportation; and David Barth, transportation safety manager at Wegmans.

NPTC's Benchmarking Survey, which is sponsored by Penske Truck Leasing, provides metrics in several operating areas. “This is information that fleets need in order to operate efficiently and at the highest level that they can,” Lager said. “We believe firmly in as much information as you can get your hands on, and this is a great source for that.”

According to the report, annual mileage among respondents decreased to 80,400. “That's a drop of nearly 5,000 miles over last year and the lowest number we've ever achieved in the history of the survey,” Moore said.

The decrease is due, in part, to companies adding distribution centers and warehouses. Most private fleets reported operating out of multiple locations, with the average number coming in at 49, up from 44 last year. "Most of our members are moving closer to the customer, and that has an impact in terms of other elements of the operation," Moore said.

Business growth, private fleet expansion, mergers and acquisitions, and a need to create a more driver-friendly network are all driving expansion. Barth said Wegman’s is among those adding facilities. “It’s had an enormous impact on the number of miles we’re running,” he said. “It’s a conscious business decision and it’s certainly paid dividends for us.”

Fleets use a combination of leasing, ownership and rental strategies. This year, 45% of fleets reported owning 90% or more of their heavy-duty power equipment, compared to 38% last year. The percentage that leases held steady at 28% while 27% use a combination of leasing and ownership.

“This year in particular, there's a lot of equipment on the market,” Lager said, adding that shifts in capacity have a direct impact on leasing and rental demand. “In 2021, when things were really tight and people had trouble getting equipment, you saw leasing go up and rental go up with it.”

Rental activity, which increased in previous years, has decreased slightly due to slowing economic and business conditions. “It's off the highs of the last few years but still pretty strong in the grand scheme of things,” Lager said. “This is where we see the drop off first, and this is where we see it pick back up first.”

The average age of equipment overall is under 4.4 years. The average age is higher for owned equipment—5.34 years—compared to those that lease all of their equipment—3.2 years.

Overall trade cycles for Class 8 trucks averaged 6.6 years, up from 6.1. Fleets that rely on leasing have shorter trade cycles for equipment—an average of 5.5 years versus 7.4 years for companies that own most of their equipment. Driven by trade cycles, leased fleets enjoy a fuel economy of 7.24 miles per gallon, compared to 6.84 for fleets that own most of their equipment.

Among respondents, 41% of fleets report outsourcing nearly all of their maintenance, while 17% said they conduct all or nearly all maintenance themselves, the lowest level in the history of the survey. Lager said trucks are becoming more and more difficult to diagnose and repair as they become more complex. “There's more technology on them, more computers, and it's just very hard to maintain them without a lot of scale,” he said.

Safety performance remains high among private fleets. “Private fleets are three times safer than the general trucking industry based on data reported in the FMCSA database,” Petty said.

Use of advanced technology has increased, and private fleets have invested heavily in active safety solutions. Nearly three-quarters reported adoption of a broad range of technologies. All respondents have adopted automatic transmissions, while 88% are using in-cab cameras, 86% are monitoring speed and 83% are using collision warnings.

The No. 1 challenge reported by respondents is cost, followed by driver related issues, including an aging driver population, recruiting, hiring and retention. For the third year in a row, the average age for all drivers in the survey remains just below 50 years of age, averaging 49.4 this year.

Despite the challenges, driver turnover dropped to 18.4% from 20.2%. The top three reasons drivers leave is to take another job, retirement or disciplinary issues. While it is always challenging to have drivers leave, Schwersenska said retirements are a good indicator of success overall. “I think it's a good thing when we're seeing folks that are in their mid-60s and able to retire from a driving job,” he said.

Schwersenska said he has also seen an increased focus on driver wellness since the pandemic. "We had so much freight to deliver at the time, and things were so wild on the outside that we really focused on taking better care of the drivers that we had on staff already and any of the new drivers that we brought on,” he said.

Average driver compensation increased to $91,081, up from $89,900 last year. Compensation has risen steadily since 2008, when it averaged $47,000.

Private fleets reported that they will continue to invest in their operations, with 48% saying that they plan to add equipment or grow the size of the fleet and 28% saying they expect to handle more of the company’s freight.

“The fact of the matter is, we want our drivers handling the majority of that freight, because nobody can handle that work as well as our professional drivers,” Barth said.

Moore added that the private fleet community is strong and continues to grow stronger. “We're setting the bar higher, and every year we continue to rise above the prior year's performance, which is a testament to the professionalism of those folks running the fleets in our operation,” he said.

Penske Truck Leasing is a Penske Transportation Solutions company headquartered in Reading, Pennsylvania. Solutions from Penske include full-service truck leasing, fleet maintenance, truck rentals, used trucks, and a comprehensive array of technologies to keep the world moving forward. Visit pensketruckleasing.com for more information.

By “Move Ahead” Staff

Every day, Penske’s technicians and customer service representatives (CSRs) keep over 400,000 vehicles moving safely across North America. This week, Sept. 21–27, we’re proud to celebrate National Technician Appreciation Week and recognize the more than 11,500 associates who power our performance.

Much of their work happens behind the scenes, but its impact is felt everywhere — keeping supply chains moving, businesses running and communities thriving. Penske technicians and CSRs do more than make repairs. They keep fleets road-ready, give customers confidence and help ensure the goods that fuel our economy reach the people who need them most.

“Behind every mile our trucks travel, every load we deliver and every promise we keep, there’s a skilled technician making it all possible,” said Mike Duquette, senior vice president of maintenance field operations at Penske Truck Leasing.

All week long, Penske will recognize technicians and CSRs across the company, spotlighting the skills, training and career paths that play an essential role in keeping the transportation industry moving.

Watch a special message of appreciation from Penske’s leadership team to Penske technicians and CSRs.

Click to view the video with Spanish subtitles here or with French-Canadian subtitles here.

Penske Logistics was honored by Whirlpool Corporation with two supply chain awards for driving innovation and efficiency with exemplary distribution center management and freight management solutions.

“We sincerely appreciate the recognition of our team and its work by our longstanding customers at Whirlpool,” stated Jeff Jackson, Penske Logistics president. “I am very proud of our associates for their continued commitment to accelerating supply chain performance for our customers.”

Penske’s distribution center management solutions earned the 2024 Whirlpool Supply Chain Supplier Award for Digital Transformation for successfully implementing a new warehouse management system (WMS) in a pilot program now expected to be replicated across the wider supply chain network.

Similarly, the company’s freight management solutions earned the 2024 Whirlpool Supply Chain Supplier Award for Customer Service by supporting inbound and outbound manufacturing processes as well as finished goods related to supplier management and trucking carrier management deliveries.

Whirlpool noted that Penske has implemented industry-leading standards of service while innovating customer service capabilities.

By "Move Ahead" Staff

In September, Penske will recognize the tremendous contributions of our professional truck drivers through National Trucking Week, celebrated in Canada Sept. 7-13, and National Truck Driver Appreciation Week, observed in the U.S. Sept. 14-20.

More than 10,000 drivers support our dedicated contract carriage, distribution center management and Epes Transport System (truckload services) teams.

Their impact is felt far beyond our roadways and loading docks. As critical players in our global supply chains, these drivers are responsible for most of the products we rely on daily—from vehicle components to groceries and crucial supplies.

“Your ability to provide timely, safe and reliable logistics services to our customers does not go unnoticed,” says Pete Bayer, senior vice president of operations. “We can count on you to deliver the excellent performance that accelerates our customer supply chains each and every day.”

Watch the full video message from Bayer; Mike Medeiros, executive vice president of operations; and Penske Logistics President Jeff Jackson below.

Click here to watch with Spanish subtitles and here for French-Canadian.

Drivers, we thank you—our supply chain starts with you!

Penske Truck Leasing is proud to mark its second annual Rental Associate Appreciation Week, honoring the associates who keep customers moving.

The week recognizes the essential role Rental associates play in helping families through life’s busiest moves and keeping businesses running smoothly.

“Our Rental associates are instrumental in delivering Penske’s legendary customer service,” said Kevin Malloy, senior vice president of rental at Penske Truck Leasing, in a video message to associates. “Their dedication and performance keep our customers coming back.”

Throughout the week, Penske will celebrate associates companywide and showcase the skills and career opportunities that make Penske Truck Rental an essential part of the transportation industry.

Penske operates more than 2,000 rental locations across North America, where associates provide personalized solutions for both household and commercial customers. From short-term rentals to seasonal fleet needs, the rental network helps businesses stay flexible and families move with confidence.

That customer connection is what inspires associates every day. Sarah Bell, an assistant rental manager in Bedford Park, Illinois, said, “You can be the reason a family moves states with a little less stress. I’ve never felt the impact of my work so deeply before, and it inspires me to maintain our high standards for customer service.”

Watch a special appreciation message to Penske rental associates below.

Click to view the video with French Canadian subtitles here.

By: Caitlin Stibitz

Penske Logistics is the recipient of a 2025 Manufacturing Innovation Award from Toyota North America. The award was handed out at Toyota’s supplier conference, in recognition of Penske’s dedicated contract carriage solutions. Penske received this honor for attaining high marks in ingenuity, efficiency and cost savings for Toyota.

Jeff Jackson, Penske Logistics president: “We thank Toyota North America for their recognition of our hard-working associates, who are dedicated to accelerating the supply chain performance of our valued customers each and every day.”

Penske Logistics supports Toyota’s plant operations in Alabama, Indiana, and Ontario, Canada.

By "Move Ahead" Staff

Whether moving across town or across the country, a do-it-yourself move using a safe, reliable Penske rental truck may be the perfect option.

For those times when hiring movers is a better fit, Penske’s security experts encourage consumers to take a few precautions to ensure the safety of your family and your cherished belongings.

Scammers, offering seemingly inexpensive moving service, use online message boards, shell websites, social media, and other online listings to attract unsuspecting consumers.

Quite often, the prices and quotes are unclear, and when the movers show up, the scammers may be using unbranded trucks or trailers.

The Federal Motor Carrier Safety Administration (FMCSA) regulates moving companies and provides information about moving fraud and how to respond to issues after the move.

If you need a full-service move, consider sourcing your movers from the American Moving and Storage Association.

What can you do if you are the victim of theft or think you've been taken advantage by a moving scammer?

If you are the victim of theft or a scammer using a Penske rental truck, call the police immediately and contact the nearest Penske Truck Rental location.

Provide the truck information, moving company, and any other details such as photos, truck plates, truck number, rental agreement number, etc.

“Move Ahead” Staff

While fireworks and sparklers are staples of Independence Day celebrations, their incendiary nature place them among the hazardous cargo prohibited from Penske rental trucks.

Penske reminds consumers that under its rental agreement flammable, explosive or otherwise hazardous materials may not be transported in its rental vehicles.

Fireworks are considered a Class 1 hazardous material by the Federal Motor Carrier Safety Administration.There are federal regulations that apply to rental truck operators regarding the transportation of hazardous materials.

In addition to fireworks, Penske prohibits carrying or hauling hazardous cargo such as full gas tanks, propane tanks, paint thinners, pesticides, fertilizer, charcoal and lighter fluid.

Being mindful of hazardous cargo is just one factor do-it-yourself movers should keep in mind as they travel to new destinations over the long Independence Day holiday weekend.

AAA projects 61.6 million people will travel by car over the holiday weekend, a 2.2% increase over last year and the highest number on record.

“Summertime is one of the busiest travel seasons of the year, and July 4th is one of the most popular times to get away,” said Stacey Barber, Vice President of AAA Travel.

“Following Memorial Day’s record forecast, AAA is seeing strong demand for road trips and air travel over Independence Day week,” Barber said. “With the holiday falling on a Friday, travelers have the option of making it a long weekend or taking the entire week to make memories with family and friends.”

INRIX, a provider of transportation data and insights, expects Wednesday, July 2 and Sunday, July 6 to be the busiest days on the road. Afternoon hours will be the most congested.

Drivers should hit the road in the morning to avoid the worst traffic. Construction, crashes, or severe weather could impact travel times. Drivers are advised to be mindful of stopped vehicles including emergency responders.

Whether moving across town or across the country, Penske Truck Rental has these tips for a successful moving day:

Penske Truck Rental offers free unlimited miles on all one-way truck rentals, discounts for AAA members, college students and members of the military as well as packing supplies and 24/7 roadside assistance. Are you ready to make a reservation? Visit the Penske Truck Rental website for more information.

With forecasters predicting an above-normal Atlantic hurricane season, fleet operators are encouraged to take steps now to prepare in the event strong storms impact your area.

The Atlantic hurricane season began Sunday, June 1 and ends Sunday, Nov. 30, but the season historically peaks between mid-August and mid-October.

Along with high winds, hurricanes can cause flooding and storm surges. If your area is affected by these conditions, planning ahead can potentially save your business and your life.

Penske has tips and resources available to help you prepare for a hurricane and guidance before, during and after a storm.

The 2024 season saw 18 named storms form with winds of 39 mph or greater. Eleven of the storms became hurricanes with winds of 74 mph or greater, and five strengthened to major hurricanes with winds reaching 111 mph or greater, according to the National Oceanic and Atmospheric Administration (NOAA).

The season included three record-breaking storms: Hurricane Beryl, the earliest Atlantic basin Category-5 hurricane on record; Hurricane Helene, which made landfall as a Category-4 storm on the Florida Gulf Coast and Hurricane Milton, which resulted in a tornado outbreak that produced 46 tornadoes and caused torrential rainfall and localized flooding.

NOAA’s outlook for the 2025 Atlantic hurricane season predicts a 30% chance of a near-normal season, a 60% chance of an above-normal season, and a 10% chance of a below-normal season.

The forecast includes a prediction of between 13-19 total named storms with 6-10 forecast to become hurricanes. NOAA predicts 3-5 will form into major hurricanes.

The Department of Homeland Security, through its Ready national public service campaign, has assembled some hurricane preparedness tips for every stage of the storm. It includes evacuation tips, what to include in a disaster supply kit and how to create a family communication plan.

Penske offers the following advice to consumers and Penske customers on what to do before a storm arrives:

Important: If you suspect your vehicle may have been flooded do not start the vehicle. Starting the vehicle may cause significant damage to the emission control system. Contact your local Penske service location or 24/7 Roadside Assistance for guidance.

Penske takes steps to ensure continued service, but there are times when delays and closures may be necessary due to travel restrictions, weather conditions, power outages or a state of emergency. Please call our 24/7 Roadside Assistance team at 1-800-526-0798 to confirm the open or closed status of a Penske facility.

By “Move Ahead” Staff

The Council of Supply Chain Management Professionals (CSCMP) has released the findings of the Penske Logistics-sponsored 2025 State of Logistics Report. The longstanding report indicates that businesses continue to navigate through a fog of supply chain and economic uncertainty. What is true today may not be true tomorrow in this rapidly changing landscape.

Created annually for CSCMP by consulting firm Kearney, this publication offers to the industry a close-up of the American economy through the lens of the logistics sector. The report further suggests ongoing fragile business optimism driven by fluctuating demand, emerging technological disruptions, and a renewed need for resilience and agility.

Notable trends and statistics include:

• U.S. business logistics costs are $2.58 trillion, which amounts to 8.8% of the national GDP. Last year, the numbers were $2.45 trillion and 8.8% respectively.

• The logistics industry in 2024 saw a return to pre-pandemic patterns in some areas, but was also marked by flat business volumes, excess truck capacity and rising operational costs.

• E-commerce continues to move along at a brisk pace, with global online retail sales nearing $6.3 trillion, resulting in more efficient last-mile delivery, increasingly agile warehousing, and a stronger demand for air freight.

• Geopolitical tensions, combined with proposed and enacted tariffs, and shifting trade regulations around the world, have combined to increase transit times, capacity constraints, rate volatility in ocean freight (leading to longer home package delivery times and delays), and a greater reliance from third-party logistics providers to deliver end-to-end support.

• Mexico overtook China as the United States’ largest trading partner in 2024. Transactions between the U.S. and Mexico topped at a record $840 billion, a 6% year-over-year improvement.

• Technology investment continues to be an essential component of the modern supply chain. Data analytics, artificial intelligence as well as robotics and automation are among the headliners supply chain leaders are working on.

Mark Baxa, CSCMP president and CEO stated: “This year’s State of Logistics Report helps supply chain professionals cut through that fog with insight, data, and direction. It highlights not only the challenges of disrupted trade flows, evolving customer expectations, and constrained capacity, but also the resilience and innovation reshaping the logistics landscape.”

Korhan Acar, Kearney partner and lead author for the State of Logistics Report, shared: “As the fog thickens, the logistics industry must move beyond short-term fixes and fundamentally rethink resilience—not as a luxury, but as a strategic imperative embedded in networks, technology, and decision-making. In a world defined by disruption, resilience is what ensures continuity, enabling agility and long-term durability. And as AI and automation drive down the cost of building resilient supply chains, the greater risk now lies in standing still.”

Andy Moses, senior vice president of solutions and sales strategy, Penske Logistics remarked: “There is a great deal of quality content in this year’s State of Logistics Report. Each day, we are helping our customers find resiliency in their supply chains, as we leverage best-in-class technology and amass capacity on a flexible basis as needed.”

By “Move Ahead” Staff

Whether you are planning a household or commercial move, rental trucks are convenient ways to transport a lifetime of belongings and memories to your new destination.

Summer heat and humidity can have an impact on items kept in enclosed spaces such as a rental truck, so great care should be taken when packing items into the truck.

Penske reminds consumers that under its rental agreement flammable, explosive or otherwise hazardous materials may not be transported in its rental vehicles. Consumers should avoid transporting items such as propane tanks, paint thinner, pesticides, fertilizer, charcoal, and lighter fluid.

Fireworks are considered a Class 1 hazardous material by the Federal Motor Carrier Safety Administration.There are federal regulations that apply to rental truck operators regarding the transportation of hazardous materials.

A general rule of thumb is that all appliances or machinery that hold gasoline or oil should be completely drained before they are loaded into a truck.

You should also avoid packing any type of combustible or highly flammable items like aerosol cans and lighter fluid.

When packing items like a gas generator, lawnmower or weed whacker, make sure to drain the gasoline and oil completely until the tank is dry. Any amount of gasoline and oil can lead to build-up of highly combustible vapor.

When packing your truck, we recommend avoiding the following additional items:

Aerosols, ammunition and guns, antifreeze, automobile batteries, cleansers containing bleach or ammonia, compressed gasses, hazardous waste, marine pollutants, matches, nail polish remover, oil or gas, paint cans, rubbing alcohol, signal flares, and weed killer.

If you have questions about whether specific items are hazardous, or you have general questions about what you are allowed to pack into your moving truck, then contact your local branch of the Department of Transportation or a moving advisor at Penske Truck Rental.

Taking these necessary steps is vital to the protection of yourself and your property. It is also important to your rental truck and the safety of other drivers on the road.

Have a question or want to reserve your next Penske moving truck? Contact the experts at Penske Truck Rental by calling 1-888-996-5415 or chat live with a Penske representative by clicking here.

By "Move Ahead" Staff

What started with nearly 3,000 competitors has come down to just 44 of Penske’s skilled maintenance technicians and preventive maintenance professionals. These standout finalists are headed to the 2025 National Tech Showdown – a high-stakes competition that celebrates the precision, expertise and pride of our frontline service teams.

“Tech Showdown is more than a contest – it’s a celebration of the talent, expertise and dedication that powers our business every day,” said Art Vallely, president of Penske Truck Leasing. “This year’s event raises the bar, sets a new standard for excellence and further emphasizes our deep commitment to investing in and developing our maintenance team.”

Over the past eight weeks, competitors moved through district and area competitions that tested their technical knowledge and problem-solving abilities through a mix of online exams and hands-on challenges. The top performers from each area earned their spot at Nationals, where they’ll compete for the top honor and unprecedented awards.

This year brings several exciting milestones. Three women are among the national finalists – a first in Tech Showdown history. Seven competitors are returning after participating in the 2023 competition. And for the first time, 12 additional finalists have been awarded Golden Pit Passes – special invitations recognizing their performance and potential.

Now in its 25th year and with the largest award pool in program history, the final round takes place June 12 at the Team Penske racing headquarters in Mooresville, North Carolina.

Want a closer look at the action? Follow along on social media as we celebrate our finalists and share more from Mooresville as the road to Nationals reaches the finish line.

By: Caitlin Stibitz

Maintaining the nation’s roadways requires periodic maintenance and even new construction.

New speed limits, traffic patterns and rights of way, as well as worker and vehicle movement, can all impact work zone safety.

National Work Zone Awareness Week, April 21-25, shines a spotlight on ways motorists and professional truck drivers can work together to keep work zone workers safe.

The Federal Highway Administration (FHWA) has joined with the American Association of State Highway and Transportation Officials (AASHTO) and the American Traffic Safety Services Association (ATSSA) to coordinate and sponsor the awareness campaign.

This year’s theme is “Respect the zone so we all get home.”

Before taking the wheel, the FHWA encourages drivers to keep the following in mind when entering a work zone.

Work zones present challenges for truck drivers – narrowed lanes, sudden stops, traffic pattern shifts, and uneven road surfaces can lead to crashes and fatalities if they are not prepared and alert. Plan your route, reduce speed, stay alert, and do your part while traveling through work zones.

Large blind spots, long stopping distances, and size constraints make maneuvering large trucks and buses in work zones particularly challenging. Passenger vehicles should be mindful that CMV drivers need to take extra precautions when driving through these areas.

Pay close attention to road workers and flaggers – give them extra room, always slow when approaching them, and be prepared to stop if necessary.

There are plenty of resources available to research your routes and check for upcoming work zones. Make sure you know of any road work before embarking on your route and when possible, use detours to avoid having to pass through these areas.

Reduce speed while traveling through work zones, paying close attention to signs and signals.

Be aware of passenger vehicle drivers around you, who may not be aware of commercial vehicle driving challenges, including large blind spots and longer stopping distances.

When approaching lane closures, move into the open lane as soon as possible – pay close attention to vehicles around you that could be in your blind spot.

Rear-end crashes are common in work zones. Obey all speeds, avoid distractions, and maintain extra space between your vehicle and the one in front of you at all times.

For more information on work zone safety, visit the FHWA website.

By “Move Ahead” Staff